Certification of coatings

The main subjects of R&D refer to the choice of hardening technology to increase service life of a particular product or create functional coatings on its surface.

Approximate plan of certification of coatings

- analysis of domestic and international experience in solving the task;

- alternative choice of hardening technologies (2-3 variants are optimal);

- study of properties of the modified surface using selected technologies on witness samples;

- optimizing hardening technology on the basis of experimental and statistical research;

- performing model tests of hardened products;

- industrial testing of lots of hardened products (full-scale tests);

- economic justification.

Used methods of study and certification of coatings

|

Property |

Method of study |

|

Thickness of modified layer or coating |

Calotest, ellipsometry, profilometry, microscopy |

|

Adhesion of coating |

Scratch Test, Rockwell Cone Impact, Tear Test |

|

Physical and mechanical properties (hardness, modulus of elasticity, elastic recovery) |

Instrumental indenting |

|

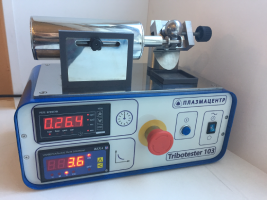

Tribological properties (coefficient of friction, wear parameters, running-in time, heat release in friction) |

Tribometry |

|

Microabrasive wear parameters |

TriboCalotest |

|

Volumetric strength properties |

Tensile tests |

|

Adhesion of lubricant (oil retention) |

Measurement of adhesion energy, rapid analysis of surface tension |

|

Residual stresses |

Using the resistive electrocontact method |

|

Coating thickness |

Anodic polarization, microscopy |

|

Roughness |

2D and 3D profilometry |

|

Dielectric properties of coatings |

Measurement of electrical characteristics of the surface layer |

|

Microstructure, element and phase composition, morphology, topography and nanoprofilometry |

Raster (scanning) and transmission electron microscopy, scanning electron microscopy with X-ray spectral analysis, scanning (atomic force) probe microscopy, BFE electron spectroscopy, X-ray phase analysis, infrared spectroscopy, X-ray fluorescence spectroscopy |

Equipment for the attestation of coatings