Microplasma spraying (MPS)

Essence of the process

Application of 0.1-1 mm thick coatings made of powder materials heated and accelerated with microplasma jets when parts are heated not more than 150 C.

Coatings applied

On the basis of alloys of iron, nickel, cobalt, copper, molybdenum, titanium, intermetallides, hydroxyapatite, ceramics etc.

Types of coatings

Wear Resistant Carbide Coatings (WC-Co, WC-Ni, Cr3C2-NiCr)

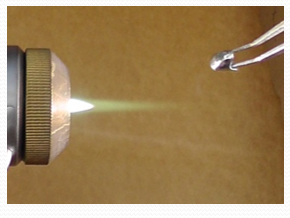

Task: application of high-performance carbide-based coatings using atmospheric plasma spraying.

Plasma jet at MPS

Gas flame at HVOF

Due to the minimum power of the plasma jet at MPS it is possible to apply coatings based on tungsten and titanium carbides.

Roughness Coatings on Dental Crowns and Dentures

Task: application of coatings that increase the area and roughness of the surfaces to which the tooth enamel will be applied.

Benefits

- coating directly in dental laboratories;

- spray spot diameter 2-5 mm;

- spraying on thin-walled parts of small dimensions;

- low power consumption (up to 2.5 kW);

- minimal noise level (about 50 dB).

MPS uses low plasma power, so the thermal load on the substrate is small and does not lead to overheating of thin-walled and small-sized parts.

Biocompatible Coatings (Hydroxyapatite, Titanium, Tantalum)

Task: adjustable porosity coating by atmospheric plasma spraying.

Coated endoprosthesis

Degree of crystallinity of coatings - ≈ 80% (at initial powder - 90%)

Benefits

Application: hip, elbow, knee endoprostheses, proximal modules, implants for interbody spondylosis, dental implants, etc.

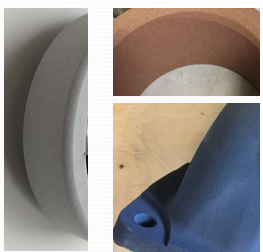

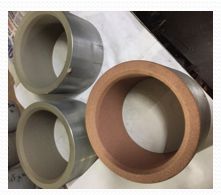

Antifriction and Friction Coatings (Mo, Cu, Bronze, Intermetallics)

Task: coating of small-sized and low-rigidity parts with minimal heat input.

Slide bushinas

3D printer rollers

Piston

Heat Resistant (Inconel, Stellite, Hastelloy) and Ceramic Coatings (TiO2, Al2O3, ZrO2, etc.

Task: application of heat-resistant and ceramic coatings on small-sized parts.

Friction disc

Collector

Cast iron composition sensors

Spatula

Plasma powder jet

Shaft

If you are interested in the technology we offer or you would like to get more details, please, contact us by email: coatingcenter.il@gmail.com.