Plasma pulse deposition (PPD)

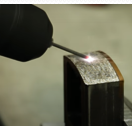

Essence of the process

Application of coatings with thickness of 10-100 mm at simultaneous melting of the metal rod and point surface of the base material at heating of parts not more than 30 C.

Coatings applied: on the basis of tungsten and titanium carbides, alloys of copper, nickel, cobalt, iron, molybdenum, graphite, intermetallides, etc.

Types of coatings

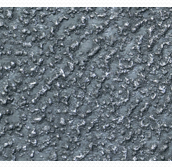

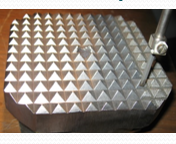

Abrasion and Erosion Resistant Coatings

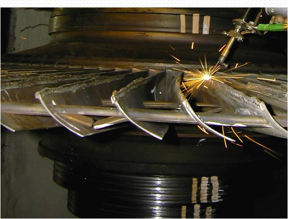

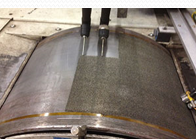

Turbine blades

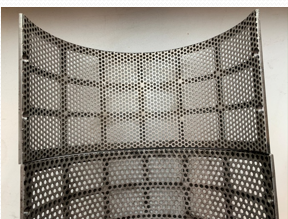

Shredder grid

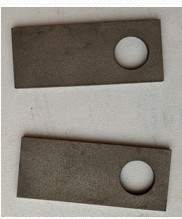

Mixer blades

Hooks for climbing

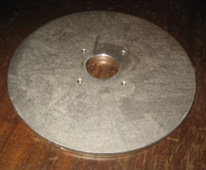

Dispenser disk

Pipe (lead-in chamfer)

Application: grids and threshers of separation and grinding equipment, blades of steam turbines, linings of special devices, pallets of mixers, etc.

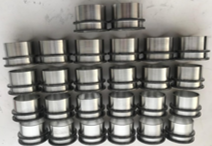

Friction Coatings

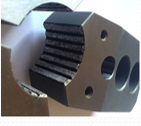

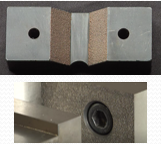

Cams

Jig bed

Collet

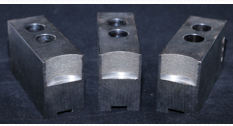

Pressure pads

Collet chuck

Shoe

Clamps

Tapered stop

Application: collets, grippers, jaws, clamps, cams, shoes, inserts of machine tools, drilling rigs, oil, gas and other equipment, etc.

Wear-Resistant and Special Coatings

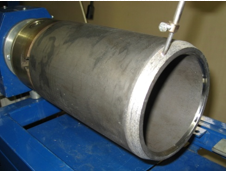

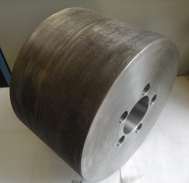

Brake drum

Thread die

Pipe grip

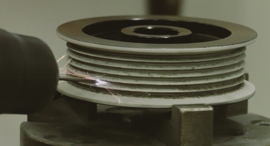

Pulley

Supercharger pulley

Tungsten coating of X-ray tube anodes

Graphite coatings

Application: anti-slip protection and special applications.

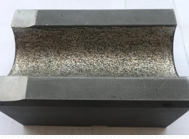

Coatings Based on Tungsten and Titanium Carbides

Roller

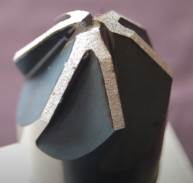

Countersink

Axe

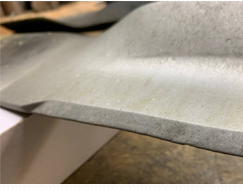

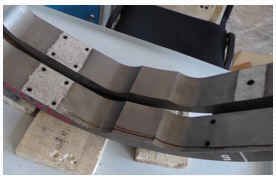

Knife

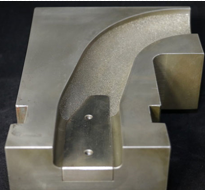

Pipe bending mandrel

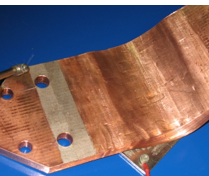

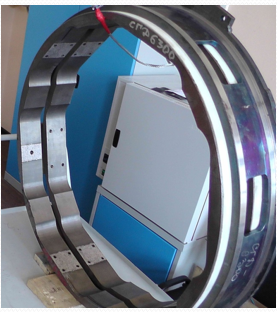

Electrically Conductive Silver Coatings

Contact surfaces of electrical machines

Contact surface of the

copper busbar

Mating ring

Application: reduction of transient electrical resistance in contact connections of busbars, current conduits of electric machines, transformers, etc.

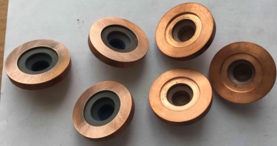

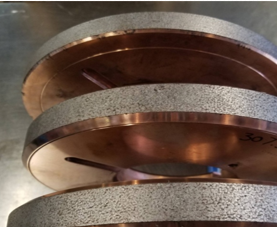

Corrosion and Erosion Protection Coatings for Copper Alloys

Contact machine electrodes

Suture machine rollers

Welding machine mouthpieces

Application: electrodes of machines for spot, seam and relief welding of galvanized metals, mouthpieces for MIG welding, etc.

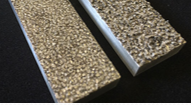

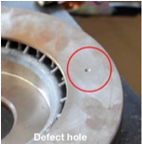

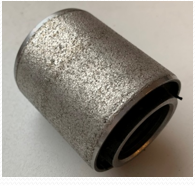

Coatings for Repairing Defects and Restoring Dimensions

Pore defect

Molding defect

Shaft mounting surface

Mounting surface

of the rubber-metal

joint (silent block)

Application: correction of casting defects, machining defects, restoration of dimensions of worn parts.

If you are interested in the technology we offer or you would like to get more details, please, contact us by email: coatingcenter.il@gmail.com.